The Refurbishment Process

Restored by Hand. Built to Last.

At Coffee Machine Emporium, we go well beyond a basic clean or service. Every espresso machine is fully stripped, cleaned, rebuilt, and tested to deliver performance that rivals a brand-new machine. Our technicians work by hand using only genuine parts.

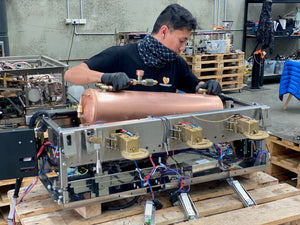

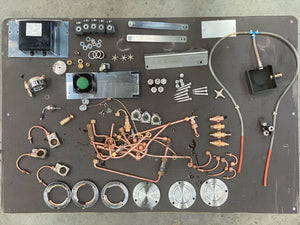

Step 1: Complete Machine Disassembly

Each machine is fully dismantled down to the frame — every boiler, group head, tap, pipe, valve, and panel is removed.

This includes:

- Steam boiler, brew boilers & boiler caps

- Group heads and full head assemblies

- Valves, solenoids, and flow restrictors

- Steam arms, taps, and internal frame parts

- Electrical wiring and fittings (if needed)

We leave no part untouched to ensure we can rebuild each unit from the inside out, eliminating any hidden wear or faults.

Step 2: Descaling and Deep Chemical Clean

All metallic components (boilers, pipes, fittings, etc.) are submerged in a commercial-grade chemical bath for up to 24 hours.

This process removes:

- Scale and mineral buildup

- Old coffee oils and organic residues

- Oxidation and internal corrosion

Parts are then rinsed, dried, and hand-polished before reassembly, ensuring optimal performance and restored shine.

Step 3: Powder Coating and Exterior Restoration

Once disassembled and cleaned, all body panels and external components are carefully prepped and sent for professional powder coating. We use durable, chip-resistant finishes available in matte, gloss, satin, or textured styles, with a wide catalogue of colours to suit your space and branding.

- Panels undergo thorough prep to ensure adhesion and finish quality

- Powder coating is applied with precision and inspected for consistency

- Panels are fully quality-checked before reinstallation

After coating, panels are hand-fitted and aligned, ensuring the machine looks as flawless as it functions.

Step 4: Rebuild

We rebuild each machine using only genuine La Marzocco and OEM parts. Our service covers all replaceable components according to a 12-month factory maintenance schedule, often going beyond where needed.

- Full steam wand & tap rebuilds (valves, seals, seats)

- Group head servicing (valves, gaskets, screens)

- New pressure stats, anti-vac valves & safety valves

- All seals, washers, and gaskets replaced

Pump and motor checked or replaced if out of spec - Electrical components tested for reliability

We don’t just service — we rebuild every element to perform like new.

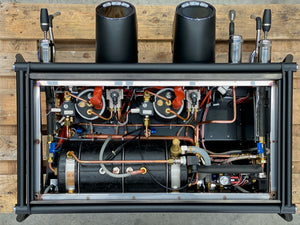

Step 5: Reassembly and Bench Testing

Once rebuilt and refinished, the machine is reassembled and put through multi-point bench testing:

- Calibration of brew temperature and boiler pressure

- Testing solenoids, flow rates, and back pressure

- Verification of pump performance and responsiveness

- Extended steam power testing

We only move forward once the machine passes every rigorous test.

Step 6: Final Quality Control and Delivery Prep

Before shipping, every machine undergoes a full pre-delivery inspection including:

- Pressure and leak testing under full load

- Steam and brew calibration checks

- Taste testing to ensure clean, balanced extraction

- Final exterior cleaning and polishing

- Secure packaging for safe transit

We also provide a quick-start guide and ongoing support post-sale to help with installation and care.

What Sets Us Apart

Cost-effective — like-new performance without the new price

Eco-friendly — extending machine life to reduce waste and environmental impact

Custom finishes — wide colour selection to match your café aesthetic

Backed by experience — trusted by cafés, caterers, and serious home baristas across Australia

Only genuine La Marzocco parts, no shortcuts

Every machine rebuilt by hand, with transparent process updates

Want a Quote or More Info?

Contact us to discuss your machine, refurbishment options, or turnaround times. We’re happy to provide before/after photos, walk you through the process, or recommend accessories to pair with your machine.